Does your source qualify for a Predictive Emissions Monitoring System (PEMS)?

Request a source evaluation today.

PEMS Pro-Logix 60Predictive Emissions Monitoring Systems for EPA PS-16 Compliance & Process Measurements

PEMS Pro-Logix 60 is a PLC-based emissions monitoring and reporting software for sources qualifying under 40 CFR 60 Appendix B (boilers) and 40 CFR Part 75 Subpart E. Multiple sources can be monitored with data and controls access for local, network and remote operators.

PEMS Pro-Logix 60™ calculates

criteria pollutant emissions with CEMS-level accuracy, thereby lowering

operating costs and increasing reliability. Deliver real time results

over your Ethernet/IP networks for the highest system visibility

available..

Easy to Use.

High Performance. High Reliability.

Easy to Use.

High Performance. High Reliability.

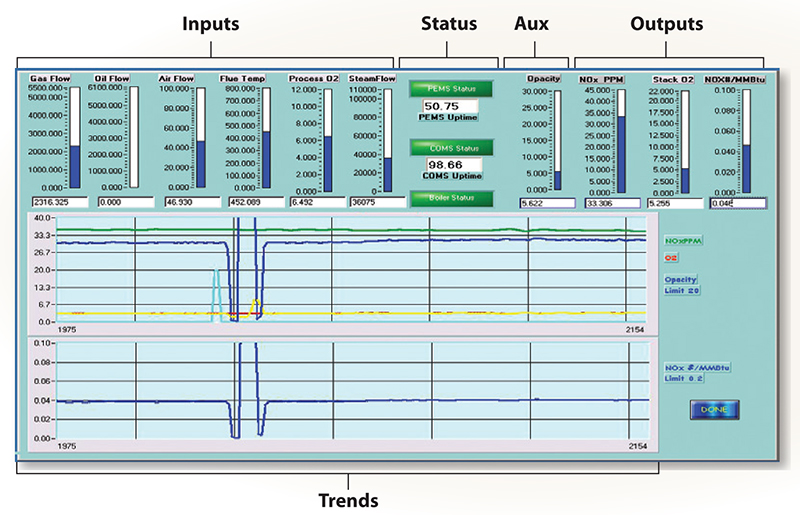

PEMS Pro-Logix 60 combines its comprehensive dialogue screens and monitoring analysis tools into an easy to use interface. PEMS Pro-Logix 60 offers all the monitoring capability needed to perform accurate data collection and real-tme analysis. PEMS Pro-Logix 60 runs efficiently providing constant visibility via real-time data, trending and customizable reporting.

PEMS Interface Customization

One of the unique features of PEMS Pro-Logix 60 is its programming flexibility.

Full Featured Predictive Emissions Monitoring SystemPEMS Pro-Logix 60™ is a full-featured, predictive emissions monitoring software for qualified sources under the EPA PS-16 audit standards for compliance with 40 CFR Part 75 Subpart E and 40 CFR Part 60 Appendix B regulations for monitoring nitrogen oxides and oxygen at industrial sources. PEMS Pro-Logix 60™ uses a statistical hybrid model to provide real-time emissions predictions from a wide range of operating input parameters with CEMS-level accuracy and reliability.

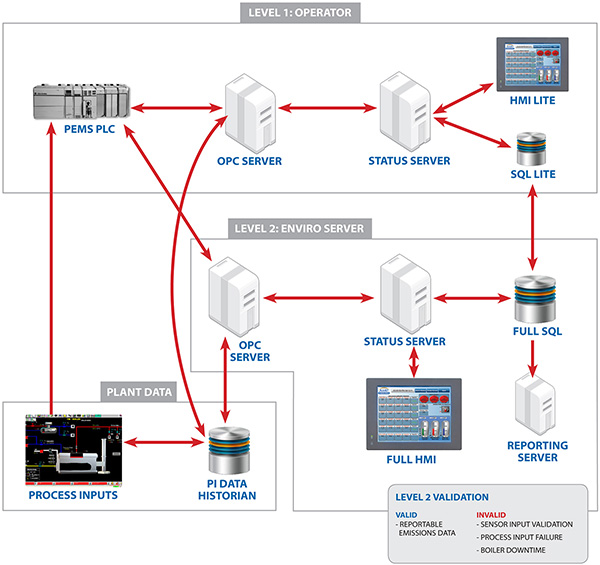

Open Architecture. Allen-Bradley PLCs. HMI>Network Interface. Our open architecture PEMS ProLogix 60™ data acquisition and reporting software, through its HMI>Network Interface™ and Allen-Bradley® PLC platform, provides network connectivity and remote operation.

Real Time & Historical Displays. PEMS Reporting Suite.PEMS Pro-Logix 60™ has customizable real time and historical display graphs to allow monitoring of emissions and process parameters. The PEMS Pro- Logix 60™ Reporting Suite provides Part 60 compliant reporting, including daily calibrations, emissions reporting, and rolling averages.

PEMS Remote Operation. Alarms and Notification.PEMS Pro-Logix 60™ controls operations and monitors system health status. User-configurable email alarms - critical and noncritical - can be configured across your monitoring network. Remote access provides administration level operation controls and troubleshooting tools to locate PEMS faults.

Process Input Sensor Validation & Error CorrectionFrom source data collected during process characterization, the PEMS Pro-Logix 60™ provides dynamic process sensor validation and error correction, along with data acquisition functions such as startup, shutdown, and other historical events.

Data Redundancy. Data Distribution.With DAS Pro-Logix 60™, data redundancy is provided at the PLC and polling computer prior to distribution to Ethernet/IP-based networks. Any data transfers that are interrupted by network disconnections are automatically restored to all servers.

A Pedigree PEMS

A Pedigree PEMSAt the Oak Ridge National Labs, the original CEMS was replaced with PEMS Pro-Logix 60™ according to EPA’s recently promulgated PS-16 monitoring requirements for all 40 CFR 75 Subpart E and 40 CFR 60 Appendix B sources.

Steam Operations Management

Steam Operations ManagementAs the operations management for steam generation at a nonwoven fabrics plant in Tennessee, Constellation Energy selected AMP-Cherokee’s PEMS Prologix 60™ for emissions monitoring of three boilers.

Contact AMP-Cherokee today at 800.399.4236 or at sales@ampcherokee.com for a free consultation on your compliance monitoring and process performance requirements.